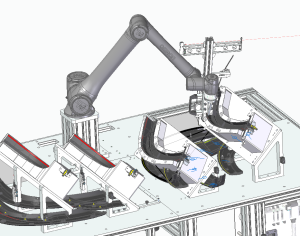

Innovative and creative industrial robots

Industrial robots are automated, programmable machines designed to perform dangerous activities for people, as well as ordinary tasks that may require high speed and precision. Due to their versatility, they can be used in all types of sectors in order to perform a wide range of activities. Automation is crucial in a fast-paced world. These multipurpose machines feature robotic arms that operate on three axes, handling tasks in various industries. Their implementation on factory assembly line is possible everywhere, from automation manufacturing to food processing companies, as well as pharmaceuticals. Originally, they were designed to mimic human actions and today they are key factors in the production process of several industries. The controller is one of the most important components, working as the brain of the robot designed to control movements through a computer system that will program the instructions of the tasks to be performed.

Some features of industrial robots

Every industrial robot must have six axis in order to be able to move freely within 3-dimensional space. The kinematic may be considered serial, since all its axes are built on each other. Sensors provide extremely precise movements in order to perform any single task, such as material handling or product assembly. Industrial robots may handle heavy loads; however, they can be extremely reliable when performing tasks such as packaging small items. Thanks to better technology especially in cloud based computing, industrial robots boost quality and productivity. They can be described as a fixed body which comprise connected components that mimic human movements, such as

- The robotic arm, modelled after a human arm. It features joints and electric motors which provide flexibility and control their movement

- The end- effector resembling a hand. Common end-effectors are cutters, drills, grippers designed to perform tasks such as cutting, assembly, grasping

Cartesian Robots

There are several types of robot with different features. The widely used both in production line assembly and logistics cartesian robots are designed just like the XYZ axes on the graph. They move in straight lines and are a good solution due to the accuracy and repeteability that specific tasks require. Cartesian robots are easy to customize in terms of speed, precision and number of axes. And when it comes to maintenance, most technicians can handle repairing or replacing components—whether it be an axis, drive or motor. The work space is a limited area, so they are easily controllable, and are suitable for specific tasks on the line, such as welding. However, they are also good tools for loading and unloading operations in logistics, though the rigid structure prevents rotary movements that articulated robots feature.

Loads of applications, real pros

Since the 1980s, industrial robots have become commonplace to perform risky welds, either arc welding or spot welding. Due to precision and speed, they can prevent workers from inhaling carcinogenic fumes and save them form burns. In automotive and aerospace industries, robots can be used for painting and coating applications. Once they ensure uniform application they reduce waste, and improve the overall quality of the finished product. Industrial robots can be employed for quality control and inspection tasks as they are equipped with advanced sensors. In order to align quality standards goals, they identify defects or measure dimensions accurately. Industrial robots can be employed for packaging tasks in warehouses and distribution centers where they pick, sort and pack products. Speed and accuracy are keys to assist staff in new industries such as eCommerce, where they often need to complete order fulfillments within few hours.

Collaborative, industrial robots over the years

Industrial robots can be defined as collaborative, being designed to work together with people and collaborate in performing tasks. These are highly evolved robots since they are equipped with sensors and cameras that allow them to detect the presence of operators. So they can easily adapt their movements in order to avoid any type of accident. The field of industrial robotics has steadily grown due to the development of other technologies, and the latest advancements in software and Computer hardware. It all began when inventor George Devol created unmate, the first industrial 1954 patented robot. Devol, whose collaboration with Physicist and Engineer Joseph. F. Engelberger led to the creation of Unimation in 1962, was a pioneer who founded a pioneering company. During the sixties and the seventies Industrial robotics has evolved into an industry manufacturing robots who began to perceive and understand the surrounding workplace.

Get in Touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Email us

support@gmail.com